Application seals play a crucial role in equipment performance, whether to maintain pressure, prevent leakage or keep contaminants out.

The life and reliability of a seal can make a difference in reducing friction, extending maintenance and increasing sustainability. It is therefore important to know the different types that exist and the various industrial applications for which they are best suited when selecting the best sealing solution for your company.

In this article, we will guide you through seven different types of seals for power transmission, hydraulic, fluid handling and custom engineering applications.

Seals for rotary application

Power transmission seals are most often used in rotating applications to seal the gap between a rotating and a stationary component or two components in relative motion. The two types of seals most commonly used in power transmission applications are radial seals and axial seals.

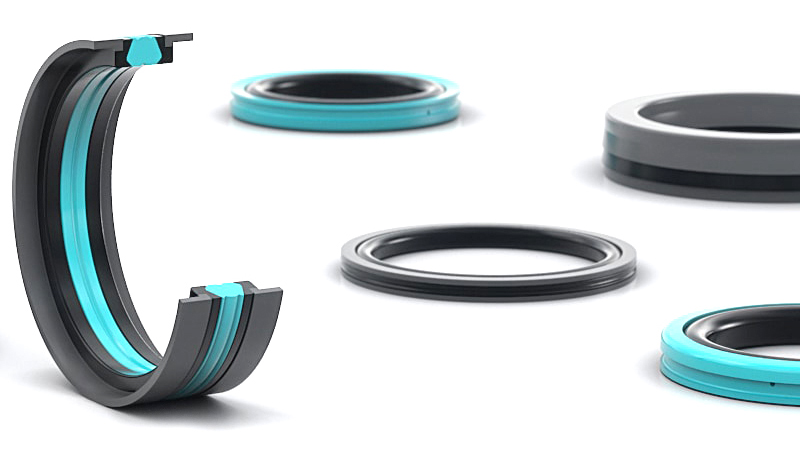

Radial shaft seals

Designed to protect bearings, maintain lubricants and improve system reliability, radial shaft seals incorporate a sealing lip, metal housing and tensioning spring, as well as a dust lip. This type of seal can be used in a wide range of applications, from small high-speed machine tools to large wind turbines.

Axial seals

Axial seals are designed to seal axially against a surface perpendicular to the shaft or pin, serve as a reliable secondary seal and tolerate minor misalignment. This type of gasket is best used in heavily contaminated environments exposed to sand, dirt, mud and water.

Hydraulic seals

Hydraulic seals are intended to separate or block fluid in reciprocating motion applications and can be shaped or machined for different factors, such as operating temperature, cylinder speed and operating pressure, medium, etc. They are used in machinery equipment in conjunction with two different types of seals: piston seals and rod seals.

Piston seals

Piston seals are usually double-acting, but there are also single-acting piston seals. They ensure that fluid does not pass around the piston pushing it down into the cylinder, while allowing an oil film to minimize friction and wear. This type of seal is often used in hydraulic presses and agricultural and industrial machinery.

4.Stem seals

Rod seals are used to seal the loss of oil a thin lubricating film on the cylinder rod. By means of a sliding movement between the cylinder head and the piston rod, the rod seals maintain the sealing contact. This type of gasket can be customized for use in a wide range of applications.

Seals for aggressive fluids

Seals for aggressive fluids and often have to meet some of the most stringent regulatory requirements. They are mainly used in the oil and gas industry as well as in the food and beverage industry. O-rings, back-up rings and rod and piston seals are among the most commonly used types.

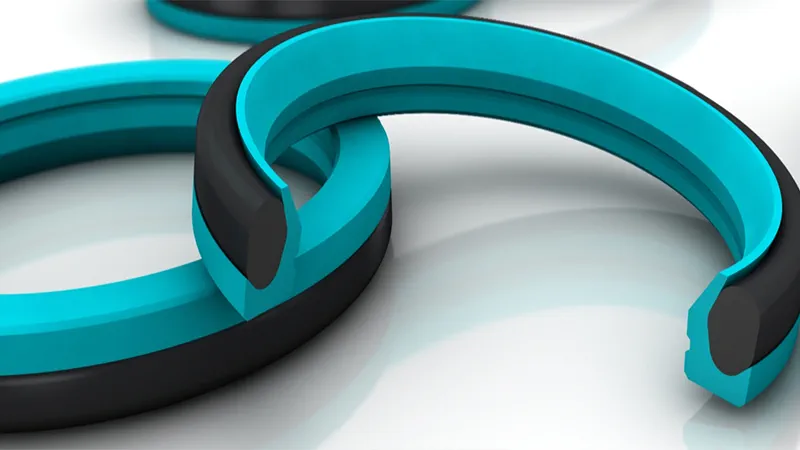

5. O-rings and support rings

O-rings and back-up rings are frequently used as a static sealing element, as they seal by their own deformation between surfaces. Support rings prevent O-ring extrusions from entering the clearance. This type of gasket is best used in applications that must withstand extreme temperatures and pressure differentials.

6. Scrapers

Wiper seals are often paired with other sealing components to achieve a tight fit and prevent contaminants from being carried into the hydraulic system with the reciprocating piston rod. This type of seal is commonly used in construction, mining and agricultural applications.

Machined joints

Machined seals can meet the unique needs of virtually any application for solutions of any dimension or design in a more customized way. Seauto’s innovative production system offers a fast and flexible alternative to the production of molded gaskets. Through extensive application engineering support and a wide selection of sealing profiles and materials, we offer on-demand manufacturing ranging from single-piece to low-volume series for sealing, fluid handling and power applications.

Search on Seauto for these different types of sealing profiles

With over 20 years of experience in industrial applications, Seauto offers unrivalled knowledge of the interaction between bearings, seals and lubrication, as well as the dynamics of alternative systems with an industry-leading reputation for offering different types of seals and sealing gaskets, and a wide range of sealing and lubrication solutions. manufactured to the highest quality for virtually any application. Seauto seals will help you improve the capacity, durability and performance of your equipment.