Gapi launches the new “Artic BLF” sealing solution, specifically designed to meet the increasing demands placed on hydraulic rod seals, where designers require reduced sliding friction and increased extrusion resistance while operating at high pressures.

The sealing problem

The main sealing problem caused by friction is heat. The heat is generated by the contact between the seal and the stem. The increase in contact surface is proportional to the increase in pressure, resulting in higher operating temperatures at higher pressures. Therefore, the solution to increased temperatures is the efficient dissipation of the heat generated by the seal. The consequence of higher temperatures is a natural softening of the gasket material, resulting in an increased risk of gasket extrusion. The most common solution to this problem is the introduction of an anti-extrusion ring mounted around the base of the joint.

Benefits and advantages of the Artic BLF sealing solution

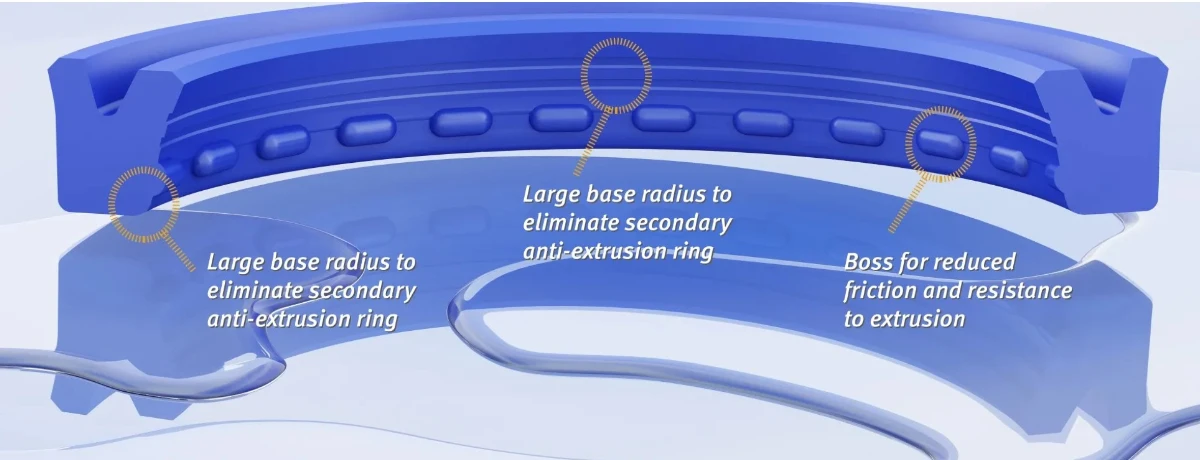

The new Artic BLF significantly reduces both the operating temperature of the seal and the resulting risk of extrusion, thanks to its unique and innovative profile. The shoulder feature present on the inner sliding face of the gasket decreases the contact area, in turn reducing friction and eliminating the base of the gasket from the clearance, thus minimizing the risk of extrusion. The addition of the channel feature not only reduces the contact area, but also allows oil to be captured within the sliding surface in front of the primary sealing lip, creating an oil chamber to lubricate the sealing lip allowing for smooth operation and further reducing friction.

Artic Seals is a brand of the GAPI group.