Description

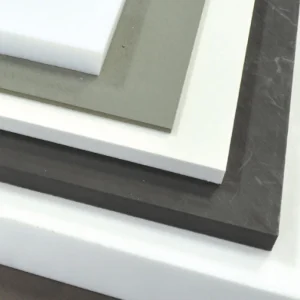

Virgin PTFE

The most outstanding characteristics of pure PTFE are:

- Wide range of working temperatures.

- High resistance to corrosion.

- Anti adherent.

- High dielectric properties.

- Low friction coefficient.

- Non-toxic / Inert.

- PTFE is a thermosetting polymer, which maintains a very high viscosity at temperatures up to +273 ºC and can be used at temperatures between -200 ºC and +260 ºC.

PTFE tubing

For this reason, PTFE is indispensable in the industry. As examples, it is applied in the manufacture of PTFE bellows for the fine chemicals industry, mechanical seals in the petrochemical industry, all types of gaskets and parts for the pharmaceutical industry, manufacture of valves for the hydraulic industry, non-stick coatings for the food industry, packaging and industrial paints, among others.

However, there are some specific applications where the properties of virgin PTFE have to be improved and are obtained by adding some filler to the PTFE. At Merefsa we can advise you on the type of cargo that best suits your needs.

PTFE and its fillers

PTFE WITH CARBON LOAD: This additive is usually added at a percentage of 25%. It improves wear resistance, being self-lubricating and load deformation, increases thermal conductivity and leaves chemical resistance unchanged; but dielectric properties are substantially modified.

APPLICATIONS: used in seals where high wear resistance under high pressure is required (piston rings for non-lubricated compressors, bearings).

PTFE WITH GLASS FIBER LOADING: PTFE is usually loaded with 25% glass fiber. This load improves wear resistance and, to a lesser degree, load deformation, leaving the electrical and chemical characteristics unchanged. The glass load may cause some abrasion.

APPLICATIONS: It is the most usual load for seals when there is rotation and movement (application in pneumatic use, hydraulic, bearings, piston ring, valve seats and mechanical parts).

PTFE WITH STAINLESS STEEL FILLER: This filler improves compressive strength and has low permeability.

APPLICATIONS: It is recommended for applications where high compression and chemical resistance are required. It is also used in dynamic applications (sealing applications and machine bearings).

PTFE WITH BRONZE LOAD: This bronze additive is added in a percentage that varies from 40% to 60%. This combination has the best wear resistance characteristics, remarkable load deformation resistance characteristics and good thermal conductivity; but it has low chemical resistance and reduced dielectric properties.

APPLICATIONS: Dynamic seals where high wear resistance under high compression set is required, but where chemical resistance is not important. (compression rings, bearings and hydraulic systems).

PTFE with bronze filler