GAPI Technische Produkte GmbH

a company of the Gapi Group, has been manufacturing injection molded parts for extreme stress applications for decades. The focus is on the use of high-performance thermoplastics such as Torlon® (PAI), PEEK or PPS.

Torlon® (PAI) occupies a special position due to its outstanding material properties in terms of thermal and mechanical stress.

Torlon® (PAI), the exotic among high-performance thermoplastic materials

Torlon® injection molded components (PAI), e.g. sealing rings for oil rotary joints, thrust washers and plain bearings, can be used over a very wide temperature range. This ranges from the cryogenic range (below -150 °C) up to a temperature above 260 °C. Thanks to its very high glass transition temperature of more than 280 °C, the mechanical properties are maintained over the entire temperature range.

In addition, Torlon® injection molded components (PAI) behave like metals under extreme conditions. For example, thermal expansion of the order of magnitude of steel can be achieved by modification with carbon fibers. Modifications with slip-optimizing additives further increase the already high wear resistance.

In addition, Torlon® (PAI) components can also be used as electrical insulators. Due to their high temperature resistance, even in the long term, they are ideal for use in electrical or electronic components. In addition, Torlon® (PAI) is characterized by its intrinsic flame retardancy and superior fatigue resistance.

New demanding applications

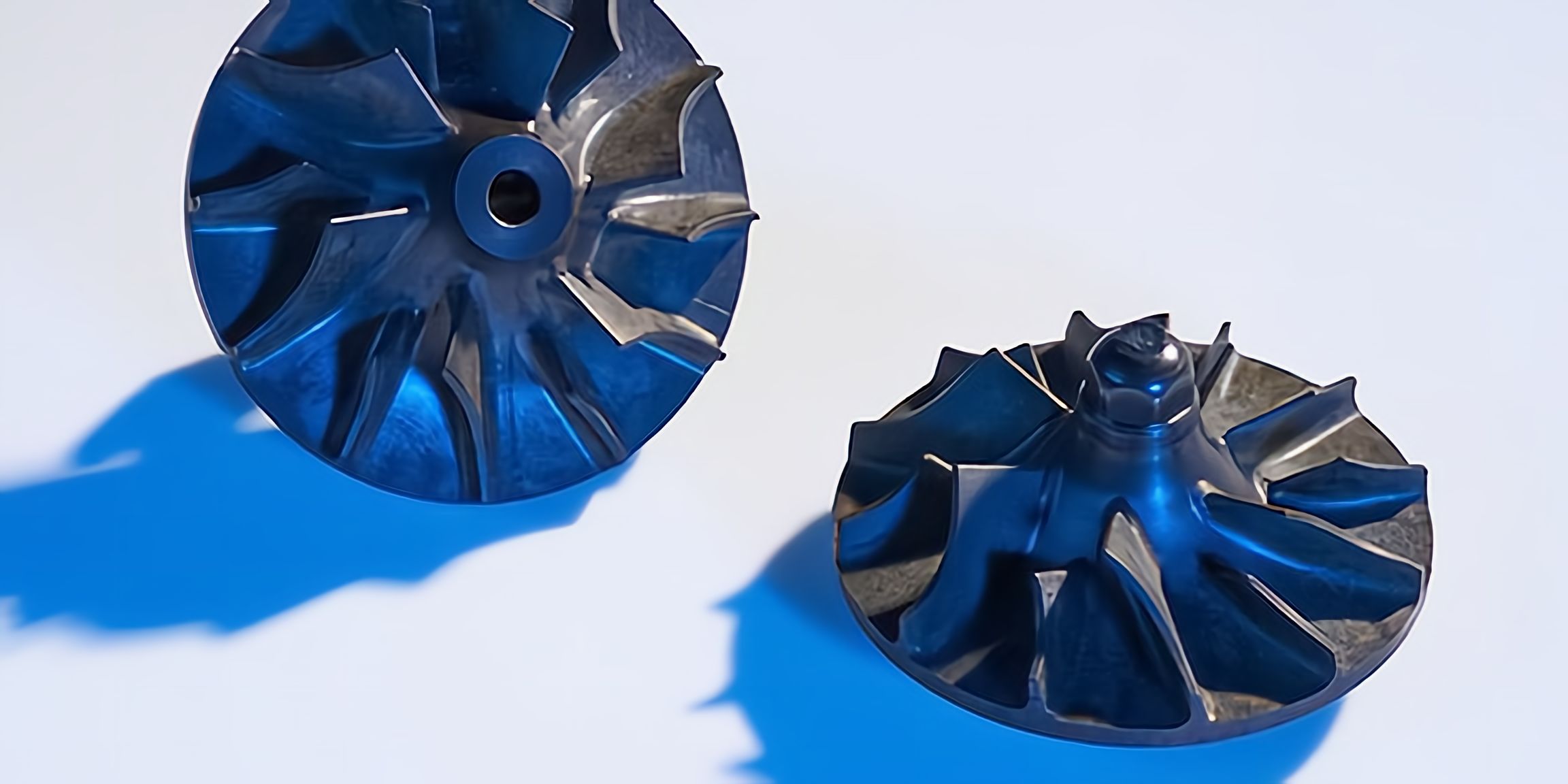

In the field of passenger car and commercial vehicle production, Torlon® injection molded components (PAI) are used as highly stressed components for the powertrain (gearboxes, clutches, turbochargers, vibration dampers, retarders).

Conventional or combustion engine drives are increasingly being replaced by battery electric drives and new drive technologies such as hydrogen fuel cells. This brings new requirements that cannot always be met by parts and components based on conventional high-performance materials.

In such a case, a custom Torlon® injection molded component (PAI) could be the solution.

In addition, Torlon® (PAI) is often superior to metallic materials and could solve application problems while reducing the weight of the part or component.

GAPI Technische Produkte GmbH specializes in the development, manufacture and sale of sophisticated components and assemblies made of high-performance plastics (such as Torlon®, PEEK or PPS), elastomers and ceramics.

With several decades of experience in the processing of high-performance thermoplastics, we are the world’s largest processor of PAI (Torlon®) materials for injection molding.